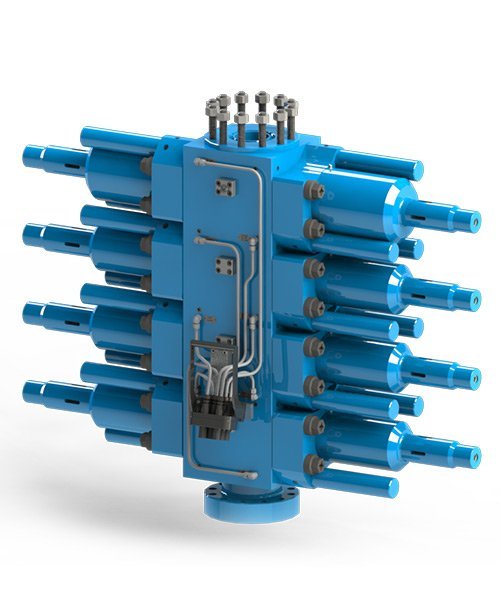

A Blowout Preventer (BOP) is a specialized unit that prevents oil spills or the uncontrolled release of crude oil or natural gas. NXL Technologies offers various pressure control Blowout Preventers (BOPs).

Our Blowout Preventers are available with internal diameters from 2-9/16” to 7-1/16” and working pressures up to 15,000 psi.

Our BOP's are available in multiple models:

- Single

- Dual Combi

- Triple

- Quad

Upgrades

- Tandem Piston Actuators

- Pressure Balanced Actuators

- Combi Rams

- Additional Shear Actuators for Combi Rams

- High-Temperature Seals

Accessories

- Internal Hydraulic Lightweight BOP

- Field Test Caps

- Trident Shear Blades

- De-Booster

- Stucchi Multi-Coupler

- Transport Stand

- Transport Stand with Test Stump

- Hydraulic BOP Boosted Actuators

- Chain Rack Bracket Kit

- Tie Down Plates

Blowout Preventer FAQs

How does a Blowout Preventer work?

Blowout preventers are important equipment to keep your operation and staff safe. A Blowout Preventer shuts off the valve leading underneath your machinery, controlling the pressure in the well to stop liquid from surfacing in a dangerous explosion or a kick.

What does a Blowout Preventer do?

The function of a Blowout Preventer is to prevent the uncontrolled release of crude oil or natural gas, which could lead to oil spills or dangerous explosions.

What equipment does NXL offer to support their Blowout Preventers?

To provide you with a complete and innovative solution for your oil & gas operation, NXL has a wide range of equipment to support our Blowout Preventers, including:

- Field Test Caps

- Trident Shear Blades

- De-Boosters

- Multi-Couplers

- Transport Stands

- Tie Down Plates